Whether it’s indoor handling or outdoor heavy lifting, your forklift truck tires directly affect safety, stability, and uptime. And for dealers and distributors, being

able to recommend the right tire isn’t just helpful – it’s business-critical.

This guide is your toolbox for talking forklift tires with confidence. We’ll break down

the different forklift truck tire types, help you match tires to real-world jobs, flag common issues before they become problems, and show you when it’s

time to swap them out.

Forklift truck tire types explained

Not all forklift truck tires are created equal. And choosing the wrong one? That can mean premature wear, poor handling, or even downtime.

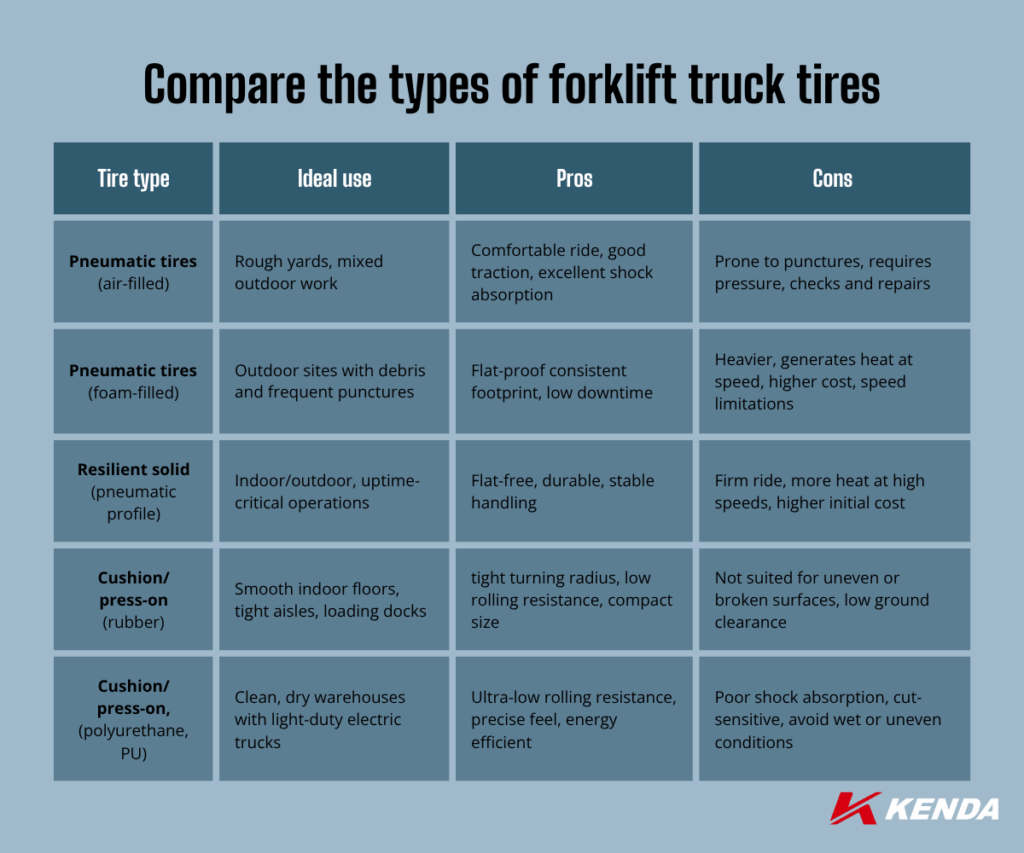

Here’s a quick look at the five most common forklift truck tire types — and where they shine:

Pneumatic tires (air-filled)

What it is: a reinforced rubber casing mounted on a rim and inflated with compressed air; load is carried by air pressure and the carcass.

Best for: rough yards and mixed outdoor work.

Pros: ride comfort, traction, shock absorption.

Cons: puncture risk; needs pressure checks and repairs.

Pneumatic tires (foam-filled)

What it is: a standard pneumatic casing injected with PU foam that cures into an elastomer, so it runs airless.

Best for: outdoor sites with frequent debris and punctures.

Pros: flat-proof, steady footprint, minimal downtime.

Cons: heavier, more heat at speed, not ideal for long distances between loading as heat is built up, higher cost; cap speeds accordingly.

Resilient solid (pneumatic profile)

What it is: a multi-layer solid rubber tyre built to pneumatic dimensions and tread style, sometimes with apertures for compliance.

Best for: mixed indoor/outdoor where uptime matters more than ride.

Pros: zero flats, very durable, predictable handling.

Cons: firmest ride, higher upfront cost, heat build-up on long fast runs, heavy – sometimes heavier than PU-filled.

Cushion/press-on, rubber

What it is: a solid rubber band bonded to a steel ring that’s pressed onto the hub (no air cavity).

Best for: smooth indoor floors, docks, tight aisles.

Pros: tight turning radius, low rolling resistance, compact fit.

Cons: poor performance on rough or broken surfaces; limited ground clearance. Very harsh driving experience and limited shock absorption.

Cushion/press-on, polyurethane (PU)

What it is: a cast or bonded PU band on a steel core, harder than rubber and highly efficient.

Best for: light-duty electric trucks in clean, dry warehouses.

Pros: very low rolling resistance, precise feel, energy efficient.

Cons: limited shock absorption and cut resistance on rough floors; avoid wet or uneven yards. Limited traction and no traction on wet smooth surfaces.

Spotlight on the pneumatic air-filled tire type

When comfort, traction, and shock absorption are top priorities, pneumatic air-filled tires are a trusted go-to—especially for forklifts working on uneven or outdoor surfaces.

These tires feature a reinforced rubber casing filled with compressed air, allowing them to flex over rough ground and absorb impact. They offer a smoother ride than solid tires, which reduces operator fatigue and protects the truck and load.

Best suited for:

- Construction sites

- Outdoor logistics yards

- Uneven warehouse aprons

- Operations needing traction and ride comfort

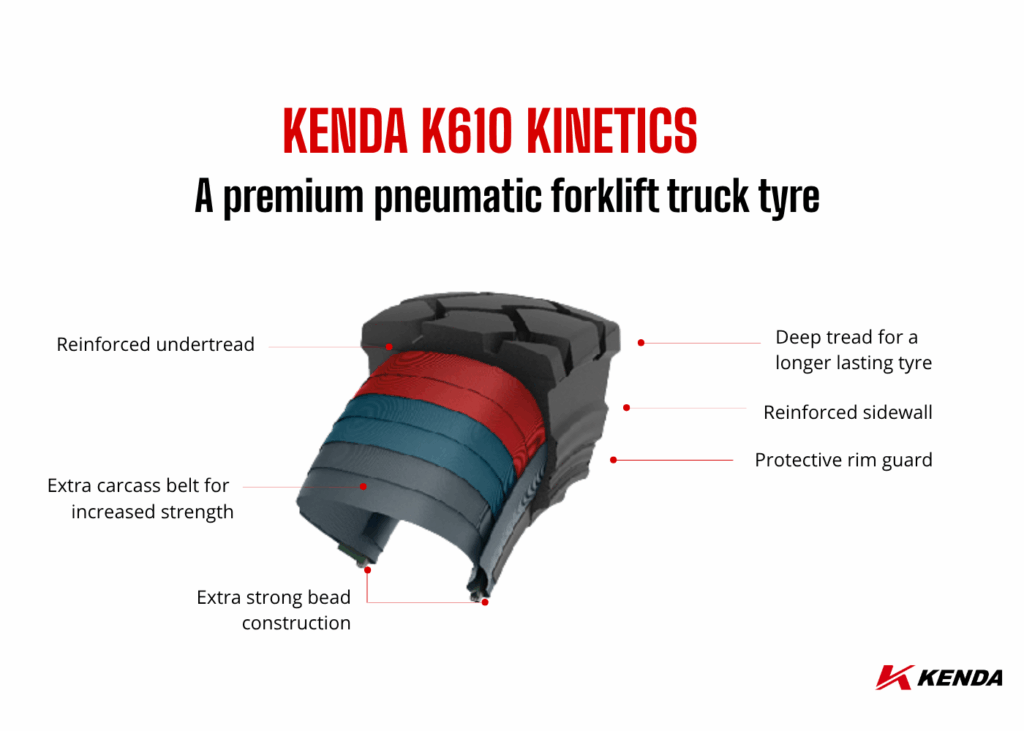

Lets look at an example – the KENDA K610 Kinetics – a premium pneumatic forklift truck tire.

Key construction features in K610 pneumatic tire:

- Deep tread pattern – For long life, traction, and mileage on abrasive surfaces

- Reinforced sidewalls – Resists cuts, chunking, and impacts

- Steel-belted carcass – Boosts load stability and heat resistance

- Strong bead construction – Ensures a secure rim fit, even in high-torque operations

- Protective rim guard – Shields the wheel from curb strikes and debris

What customers love about pneumatic air-filled tires:

- Smooth, cushioned ride over rough or uneven surfaces

- Strong traction and grip in outdoor conditions

- Lower upfront cost compared to solid options

- Effective shock absorption to protect loads and reduce operator fatigue

- Widely available in various sizes for different forklift types

Common forklift truck tire problems (and what causes them)

Forklift tire problems are often avoidable – if you know what to look for. Here’s how to spot the most common problems and what’s likely causing them.

- Rapid wear → Overloading, harsh driving, wrong tire type

- Heat build-up → Long shifts, high speeds, poor ventilation

- Poor traction → Wrong tread, wrong tread pattern

- Vibration or instability → Uneven wear, mismatched tires

- Chunking or cracking → Old age, poor storage, overinflation

- Floor damage → Wrong tread or overinflated pneumatics on soft floors

When and how to replace forklift truck tires

Even the toughest tires wear out eventually – this section gives you a quick rundown of the key warning signs, expected lifespans, and what to consider when it’s time for a change.

Signs it’s time to replace:

No tire lasts forever. Here’s how to spot the warning signs before they lead to bigger problems.

- The wear line has reached

- Visible cracks, splits, or missing chunks

- Sidewall damage

- Flat or bald spots

Typical lifespan (varies by use):

Knowing the average lifespan helps you plan ahead and keep performance on point—before the wear line becomes a problem.

- Pneumatic: 1,000–2,000 hours

- Cushion: 2,000–3,000 hours

- Polyurethane: 800–1,200 hours

Do it yourself vs professional replacement:

Some tire swaps are straightforward, others need serious gear. Here’s when to handle it in-house—and when to call in the pros.

- Press-on tires → Usually need a hydraulic press

- Pneumatics → May require specialised equipment

Disposal and recycling:

Responsible disposal matters – for the environment, and for your customers’ compliance. Here’s how to do it right.

- Work with certified recyclers or your tyre supplier

- Never burn or landfill tires illegally

How to guide your customers to the right forklift truck tire

Helping customers choose the right tire starts with the right questions. As a distributor, your advice carries weight – the right questions make all the difference.

Ask the essentials:

- Where is the forklift used? (indoor, outdoor, both)

- What surface is it running on? (smooth floor, rough ground)

- What are the load requirements? (light, heavy, high frequency)

- Are there hygiene or non-marking needs?

- How many hours per day is it used?

Quick recommendations:

- Indoor, smooth floor → Cushion or polyurethane tires

- Outdoor, uneven terrain → Pneumatic air-filled or foam-filled

- Clean industries → Non-marking tires

- Heavy use or sharp debris → Solid pneumatic with reinforced sidewalls

Watch for mistakes:

- Don’t mix tire types

- Using indoor tires outdoors

- Prioritising price over performance

Add extra value:

- Recommend replacement intervals

- Offer after-sales support

- Help customers avoid downtime — not just save on costs

Your expertise builds trust. Be the expert they rely on, not just a supplier.

FAQ - top questions forklift owners ask about tires

Can I mix tire types on one forklift?

No — it affects handling, safety, and stability. Always match type and wear level.

Are pneumatic foam-filled/solid tires better than pneumatic air-filled tires?

Depends. Foam-filled/rubber are durable and flat-proof; air-filled offer better comfort and grip.

Cushion vs polyurethane — what’s the difference?

Cushion tires handle heavier loads. Polyurethane is best for light-duty electric forklifts.

Do forklift tires need balancing?

Not like car tires, but they must be fitted properly and checked for even wear.

How often should forklift tires be inspected?

Visual checks daily. Full checks weekly or monthly, depending on usage.