Dumpers are the backbone of heavy-duty operations, from quarries to construction sites. Their performance and reliability depend heavily on the tires. As the only point of contact between your machine and the ground, dumper tires carry enormous loads, absorb impacts, and ensure traction across challenging terrain.

Proper tire maintenance and informed selection are not just about safety. They directly influence uptime, operating costs, and overall jobsite efficiency. Let’s explore how to get the best performance and longevity from your dumper tires.

What tire construction (bias vs. radial) is best suited for dumpers?

For site dumpers, bias tires are the standard choice. Their rugged structure is well suited to demanding off-road work.

Bias tires are designed with cords that run diagonally across the tire in criss-crossing layers from one sidewall to the other, forming a rigid, woven structure that gives strength and impact resistance. They are robust, resistant to cuts and sidewall damage, and ideal for short-haul or low-speed operations on rough terrain.

How do tread patterns affect traction and stability on construction sites?

Tread design directly determines how your dumper grips, turns, and wears on different surfaces. The right tread pattern not only improves traction and stability but also extends tire life and reduces downtime.

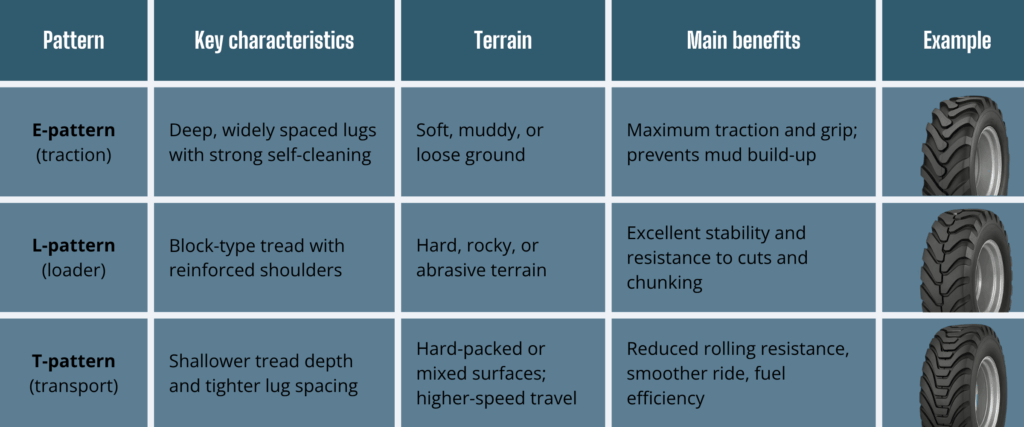

There are three main pattern types for dumpers, all with many variations: E-pattern (traction), L-pattern (loader and T-pattern (transport).

In practice, most site dumpers use E-pattern tires, as they provide the best combination of traction, self-cleaning, and durability on the soft or variable surfaces common to construction sites. Choosing the right tread ensures maximum traction, stability, and wear life for your specific jobsite conditions.

Which dumper tire solutions does KENDA offer?

KENDA Europe Specialty offers a wide range of industrial tire and wheel solutions, including dedicated dumper tires. In fact, we are one of Europe’s leading dumper tire and wheel solution providers by quantity, and have specialised in site dumper applications for many years.

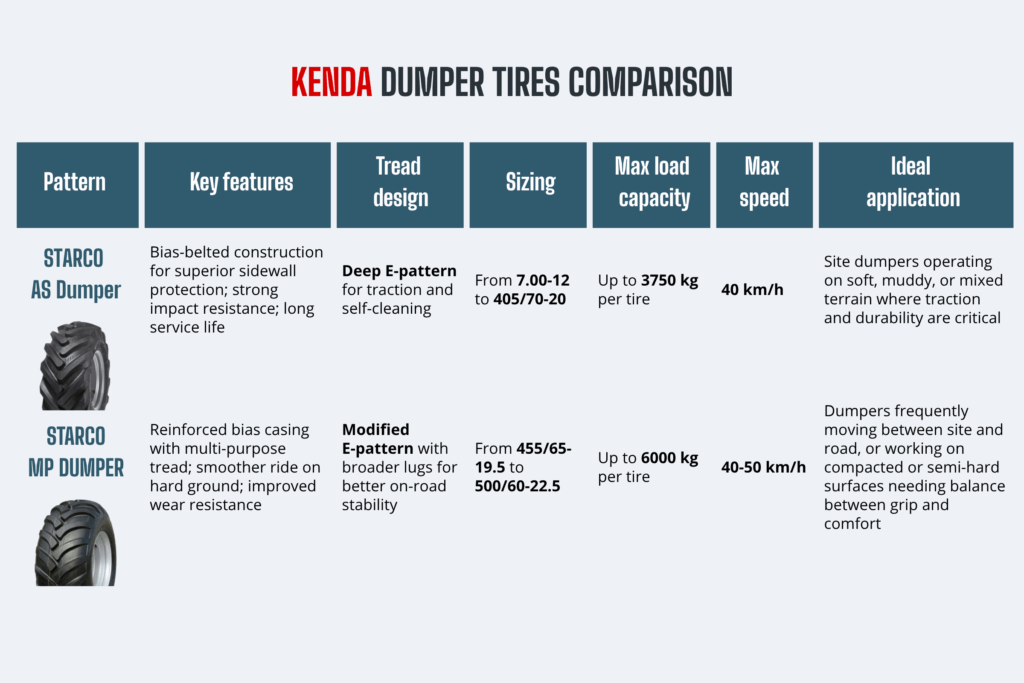

The STARCO AS Dumper tire is a versatile all-round performer for soft and mixed terrain, while the STARCO MP Dumper pattern offers enhanced tread wear and stability for operators who split time between site and road use.

Both tire designs are built with a bias-ply construction that resists sidewall impacts and supports heavy loads under tough, low-speed conditions. This design ensures exceptional strength and stability on uneven ground.

Both models feature an E-pattern tread (traction pattern) with deep, angled lugs and wide voids. This pattern is known for excellent self-cleaning and high traction, making it ideal for soft, muddy, or loose terrain. The deep lugs deliver dependable grip during uphill hauling or in wet weather, while the open design prevents clogging to maintain constant ground contact.

What are the key tire specifications (e.g., ply rating, load index, size) to consider when selecting for site dumpers?

Choosing the right dumper tire means understanding a few key specifications; the details that determine how safely and efficiently your machine performs on site.

Ply rating or load index

This number shows how much weight a tire can carry. Higher ratings mean stronger casings and greater load capacity. Ply rating is an older measure referring to the tire’s construction strength, and the load index provides an exact, standardised weight capacity. For this reason, load index is the most reliable parametre to go by. Always match the load index to your dumper’s manual to avoid overloading or uneven wear.

Tire size

Size affects ground clearance, stability, and load distribution. Wider tires spread weight better on soft ground, while taller ones slightly raise the machine’s centre of gravity. Always fit sizes approved by your equipment manufacturer.

Speed rating

Defines the maximum safe speed under load. Most dumpers work below 40 km/h, but higher-rated tires are needed if your machine travels between sites. Running above the speed rating can cause heat build-up and premature wear. See KENDA’s load/speed index chart here.

Compound and tread depth

Rubber hardness and tread depth decide how a tire grips and lasts. Softer compounds improve traction on wet or muddy ground, while harder compounds last longer on abrasive surfaces. Deeper lugs add grip but increase rolling resistance.

Getting these details right ensures the best mix of traction, durability, and safety for your operation. KENDA Europe Specialty’s technical team can help you choose the right tire size, load index, and tread design for your specific dumper and working environment.

What are the signs of premature dumper tire wear, and how can they be prevented?

Catching wear early can prevent costly replacements and breakdowns. Here are common types of damage and what they indicate:

- Tread wear

Irregular patterns can signify misalignment, overloading, or improper inflation. - Punctures and cuts

Punctures and cuts can compromise tire integrity, leading to unexpected failures and downtime. - Sidewall damage

Sidewall damage can occur when the tire rubs against obstacles or is subjected to lateral forces. - Bead damage

Bead damage can result from improper mounting or demounting or from excessive pressure or impact on the tire during operation. - Flat spots

Heavy braking, skidding, or sudden stops can result in flat spots on the tire and cause vibrations during operation.

Here are 5 tips for prolonging the life of dumper tires:

Check pressures weekly when the tires are cold. The correct operating pressure, based on load index and speed rating, can be found in the manufacturer’s manual.

Avoid overloading or uneven loading. Distribute material evenly across the dumper bed to prevent localised stress on individual tires.

Every hour counts

As this guide shows, your dumper’s performance depends on what connects it to the ground. The right tire construction, tread design, and maintenance routine can make the difference between steady uptime and costly downtime. The right choices made early can extend service life by months and keep your machine earning instead of idling.

At KENDA Europe Specialty, we design and supply dumper tires built for real jobsite demands. Whether you’re specifying for a new fleet or replacing worn-out tires, our technical team can help identify the exact solution for your site conditions and operating goals.