Tire and wheel solutions don’t live on spec sheets. They prove their worth on roads, yards, farmlands, turf, concrete, and worksites.

With a dedicated European Technical Centre, we develop and test our tire and wheel solutions for and in the conditions they are actually used in.

Our role is to remove uncertainty. We ensure that performance, compliance, and durability align with European requirements – and when reality throws a curveball, our teams adapt alongside you.

That is what we mean by tire and wheel solutions fit for life.

With a high level of technical knowledge and unparalleled know-how, we strive to be a partner you can work with rather than just buy products from. Watch the video to get a peek inside our technical centre and learn more about our partnership approach.

At KENDA Europe, development is not remote.

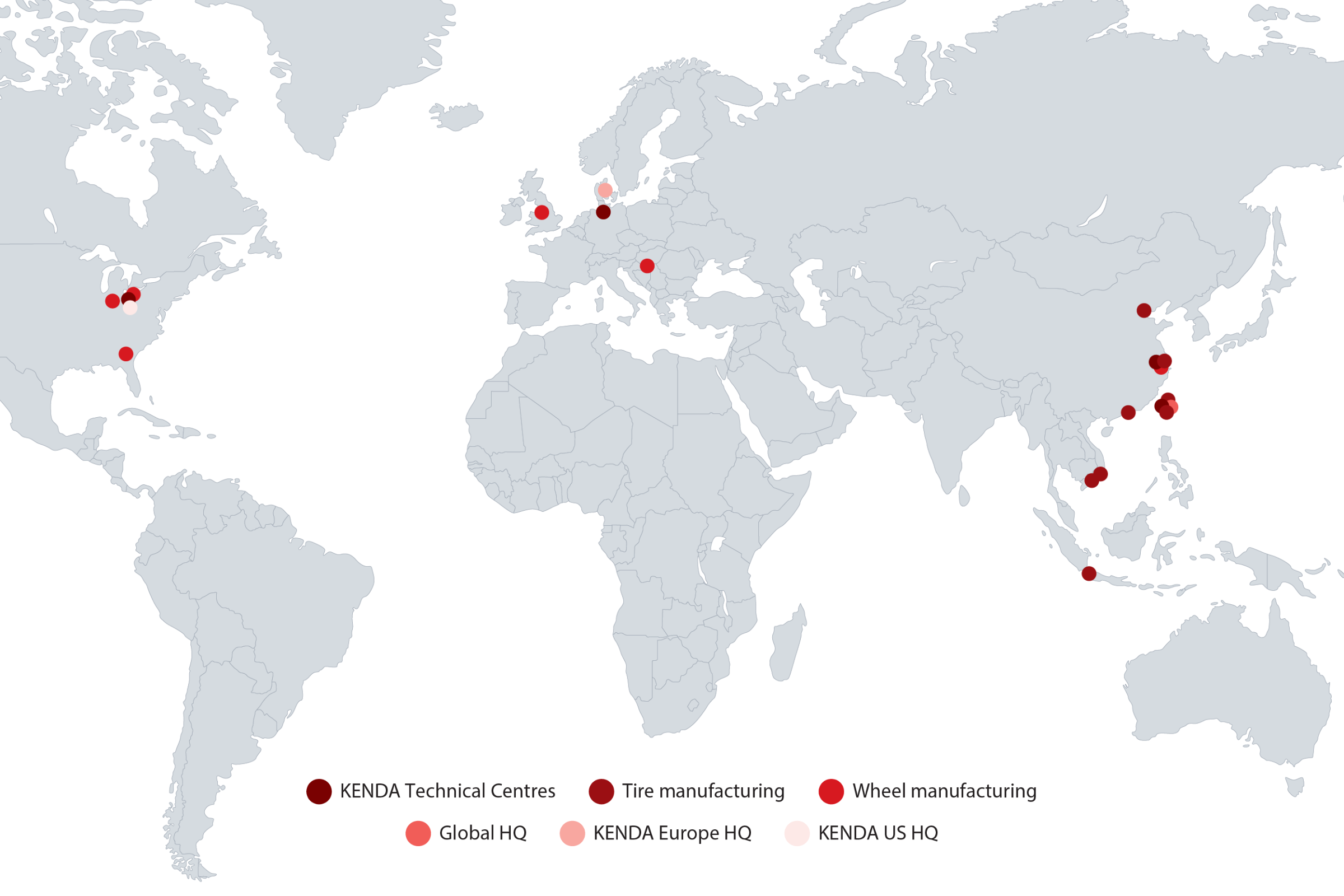

Our European Technical Centre, based in Germany since 2016, brings together more than 20 engineers focused on tire and wheel performance under European conditions – regulatory, environmental, and operational.

With additional R&D hubs connected to our manufacturing in Croatia and England, development, testing, and production stay closely linked.

Behind the local team stands a global KENDA R&D network of more than 250 specialists in the US and Taiwan.

OEMs vary. Some specify exact standards. Others describe a problem, a failure mode, or a performance gap. Our European Technical Centre supports both.

We help translate real use into measurable criteria, test against them, and document the outcome in a way that supports approvals, audits, and internal decision-making.

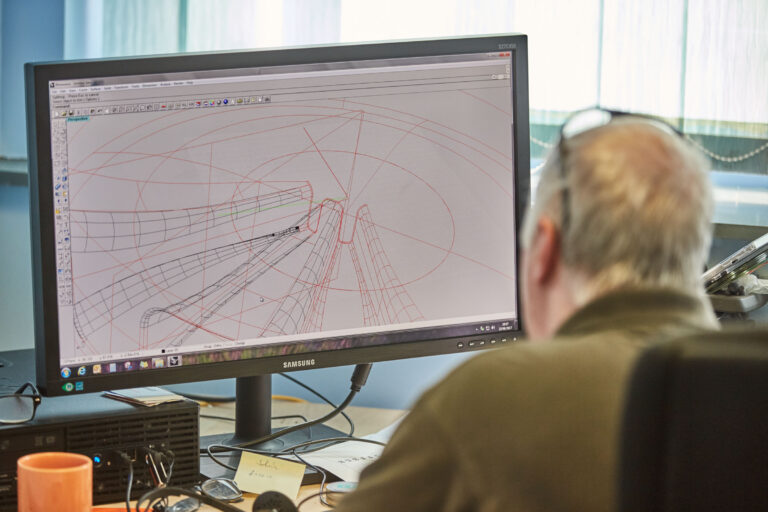

Our digital simulations, laboratory and real-world testing work together to remove uncertainty from your end solution.

Advanced computer simulations

(e.g. tire wear, composite structure)

Finite Element Analysis automation tool development

Materials research

(e.g. steel deformation, polyurethane formulation, rubber sustainability)

Tire and wheel design

(including Design Failure Mode and Effect Analysis)

Digital design simulations

(Finite Element Analysis, footprint and aquaplaning predictions, noise and weight optimisation)

Outdoor on-vehicle tests

Indoor laboratory testing

(e.g. Tire footprint analysis, Tire stiffness tests, Wheel Cornering Fatigue tests,

Radial Fatigue testing, Tire Endurance testing)

Legal and technical compliance

(e.g. REACH, sustainability, emmissions and performance requirements)

Technical documentation

(certificates, drawings, tables)

We can test how a tire carries load, interacts with the ground, and wears over time.

By analysing stiffness in four directions, footprint shape, tread geometry, and pressure distribution, we help you:

We can test how loads are transferred from a tire through a wheel and how designs perform over time.

Using 3D scanning, cornering and radial fatigue testing, and simulation of real load cases, we help you:

Regulations continue to evolve, and interpretation often decides whether projects move smoothly or stall.

Our teams continuously monitor European and international requirements and build them into design, testing, and documentation. This helps ensure:

For customers exporting globally, we also account for local and market-specific requirements early – reducing the risk of delays or rework later.

In addition to improving our existing solutions, our engineering and manufacturing teams work together to create innovative solutions for our partners, when they need something completely new.

Learn more about some of our development projects with puncture proof tire and wheel solutions:

Our European Technical Centre works closely with engineering and production at our European manufacturing sites for steel wheels in Croatia and puncture proof tire and wheel solutions in the UK.

As active members of ETRTO, ITMA, and EUWA, our engineers work inside the forums where European tire and wheel standards are defined, test methods aligned, and future regulations discussed.

This places our development work inside the standards ecosystem from day one, so you experience fewer surprises, better documentation and products that hold up in real use.

Working alongside peers, test bodies, and authorities also sharpens our decisions on materials, dimensions, and performance long before a product reaches your warehouse or assembly line.

Stay up to date on what is happening around KENDA Europe Specialty and get useful tire and wheel product and maintenance knowledge.

We will update you an average of 4 times per year.